First of all thanks for your time looking over my project!

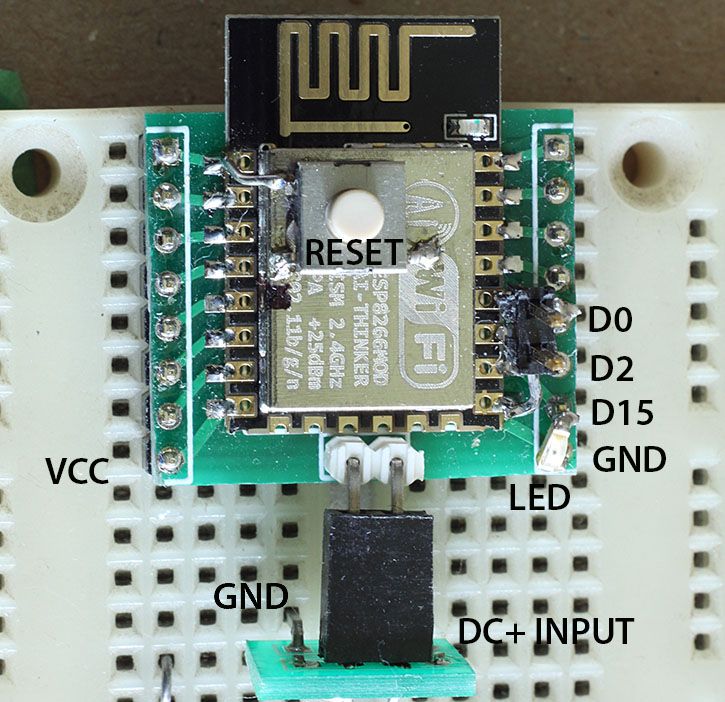

Regarding the clearing of the antenna: I will put the pcb in an enclosure, therefore there is not much room at the top (left of the picture) to move the esp antenna completely out the board, but I think 5mm is possible. And I will remove the rest of the wires blocking the bottom of the antenna, thanks for that...

The space on the lower right is for a switch which I mount into the side of the enclosure, and the pins of the switch need some room, so I wanted to make as much room for the switch and the connections to the pcb as possible. But I think I could really move the relay about 1cm to the right.

Swapping the dc pins on relay 2 is a really good tip, will do that...

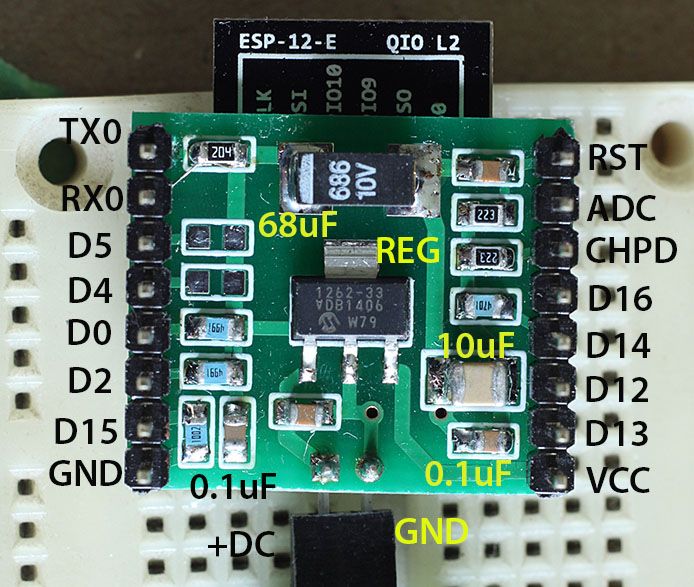

This is my first project, and I didn't know extactly how I can modify the ground plane in eagle, I just drew a polygon around the dc part and made an plane out of it, I thought it couldn't hurt and wouldn't waste so much copper (-:

Because I'm etching the board myself at home with the printer method, I tried to make wires as wide as possible and the spaces between as big as possible, so I have some room for error during the process.

I will use the 470R as my base resistor as suggested, dont want to put any more thought into that

Now that I see that there aren't any major flaws in my design, only some minor optimizations, I am really relieved , because it is just a personal project of mine I do in my spare time and don't intent to sell it or something like that. But I will try to implement your input for sure!

On the software side I made a firmware which I can use for all cases. On startup it reads config and time from my webserver in the lan. It can switch 2 relays, 2 servos and switch them on/off according to the temperature reading, or just by app I made, so I can switch my devices with the smartphone. It also has a scheduler, so a relay can be switched on and off at a specific time of day (for my pool pump), or just for a period of time.

thank you for your time !

regards

Erich